3D Printing Services for Engineering

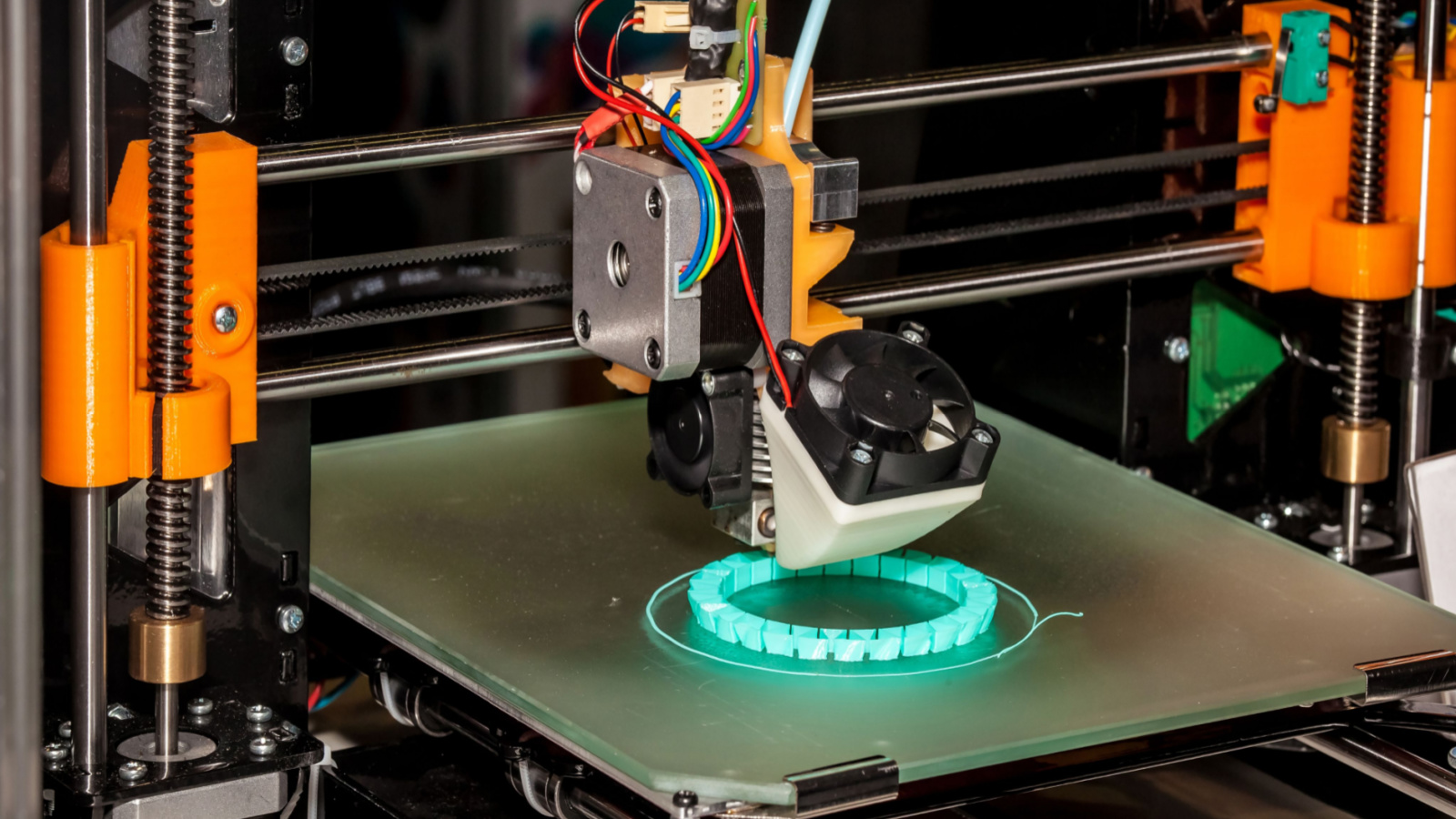

Explore Precision 3D printing built for real-world functionality

Unlock the full potential of advanced manufacturing with our precision 3D printing solutions. Whether you're creating early-stage prototypes or delivering final, production-ready parts, our technology ensures accuracy, durability, and speed at every stage. Designed for real-world applications, our 3D printing services combine cutting-edge materials with industry-leading processes to bring your ideas to life — faster, smarter, and with unmatched reliability

Functional, Mechanical & Test-Ready Parts

-

Mechanical Prototypes:

Our advanced 3D printing process delivers exceptional precision, making it ideal for producing complex, tight-tolerance mechanical assemblies. From functional hinges and snap-fits to threaded components and dynamic moving mechanisms, we ensure that every prototype operates just as it would in real-world conditions—perfect for testing, validation, and presentation.

- QC Jigs & Inspection Fixtures: Create custom quality control jigs and inspection fixtures that streamline your production workflow. Engineered for accuracy and consistency, these tools support reliable dimensional validation and help maintain tight tolerances across your entire manufacturing line.

-

Flexible TPU Parts:

Leverage the versatility of TPU (Thermoplastic Polyurethane) to produce flexible components that are both resilient and functional. Perfect for applications requiring elasticity, impact absorption, or dynamic motion—such as seals, gaskets, vibration dampers, and protective enclosures. Our TPU prints combine strength with flexibility for real-world mechanical performance.

-

R&D Models:

Accelerate your innovation cycle with high-fidelity prototypes and test models tailored for research and development. Our R&D prints are engineered for structural stress testing, form and fit validation, and functional simulation—helping you refine designs, identify issues early, and reduce time-to-market for your final product.

- Functional End-Use Parts: Skip the wait for traditional tooling — our 3D printing solutions deliver robust, end-use parts ready for real-world deployment. With materials engineered for strength and dimensional stability, you can rely on these components in actual operational environments

Prototyping for Inspection, Repeatability & Precision

- FDM & SLA Printing: We offer both FDM and SLA 3D printing to suit a range of requirements — from quick, cost-effective parts to high-resolution prints with smooth surface finishes and intricate detail

- CAD File Assistance : Our team helps refine your CAD models to ensure optimal printability, minimizing print failures and improving dimensional accuracy — especially for complex or tight-tolerance designs.

- Dual-Color & Complex Geometry: Bring your ideas to life with dual-color options and advanced support for overhangs, internal channels, and detailed features that push the limits of additive manufacturing.

- Reverse Engineering: Using 3D scanning and modeling, we recreate parts with precision — ideal for replacements, discontinued components, or design enhancements without original CAD files. .

- Toleranced Prints: We specialize in producing parts with specific dimensional tolerances for seamless assembly, interference fits, or operational integration with other mechanical systems.

Working Models for Gearboxes, Drives & Motion Testing

-

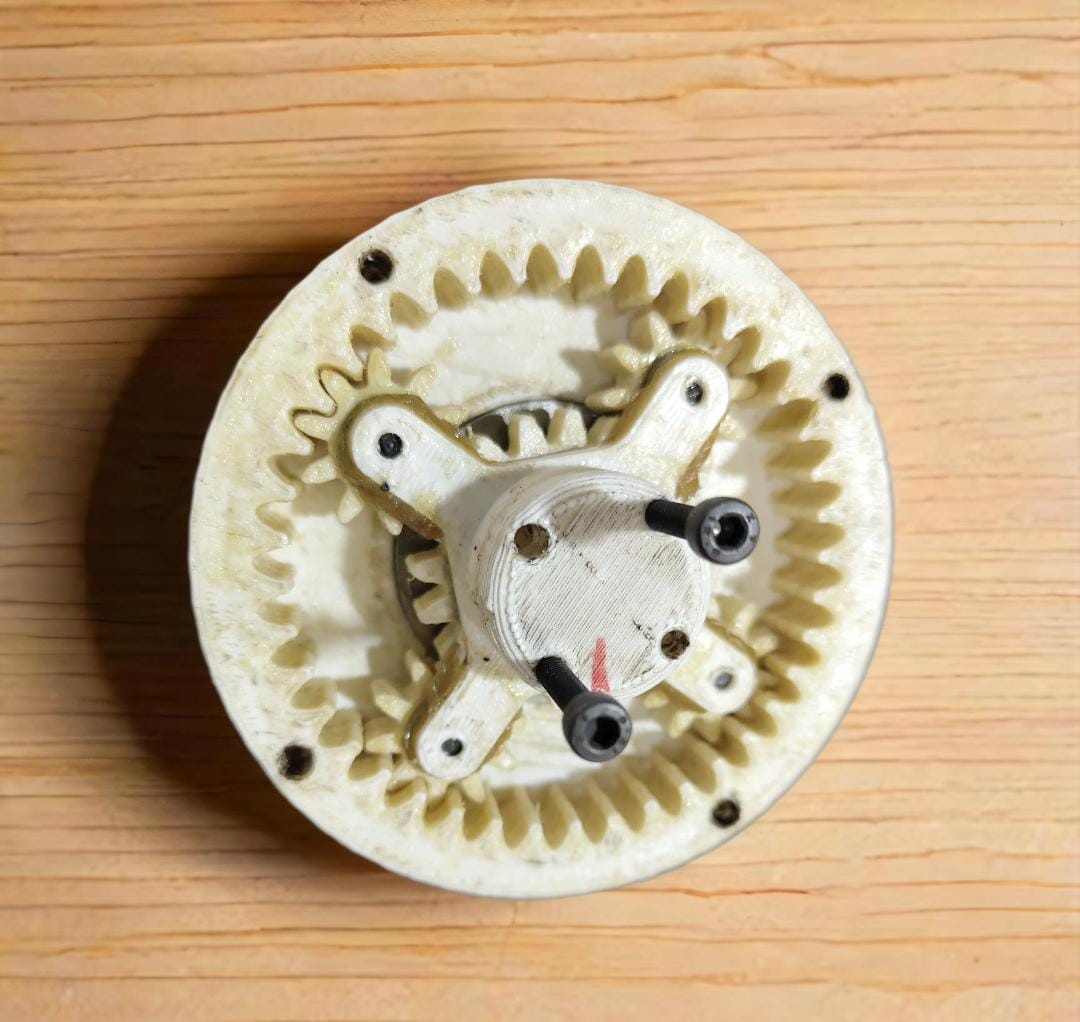

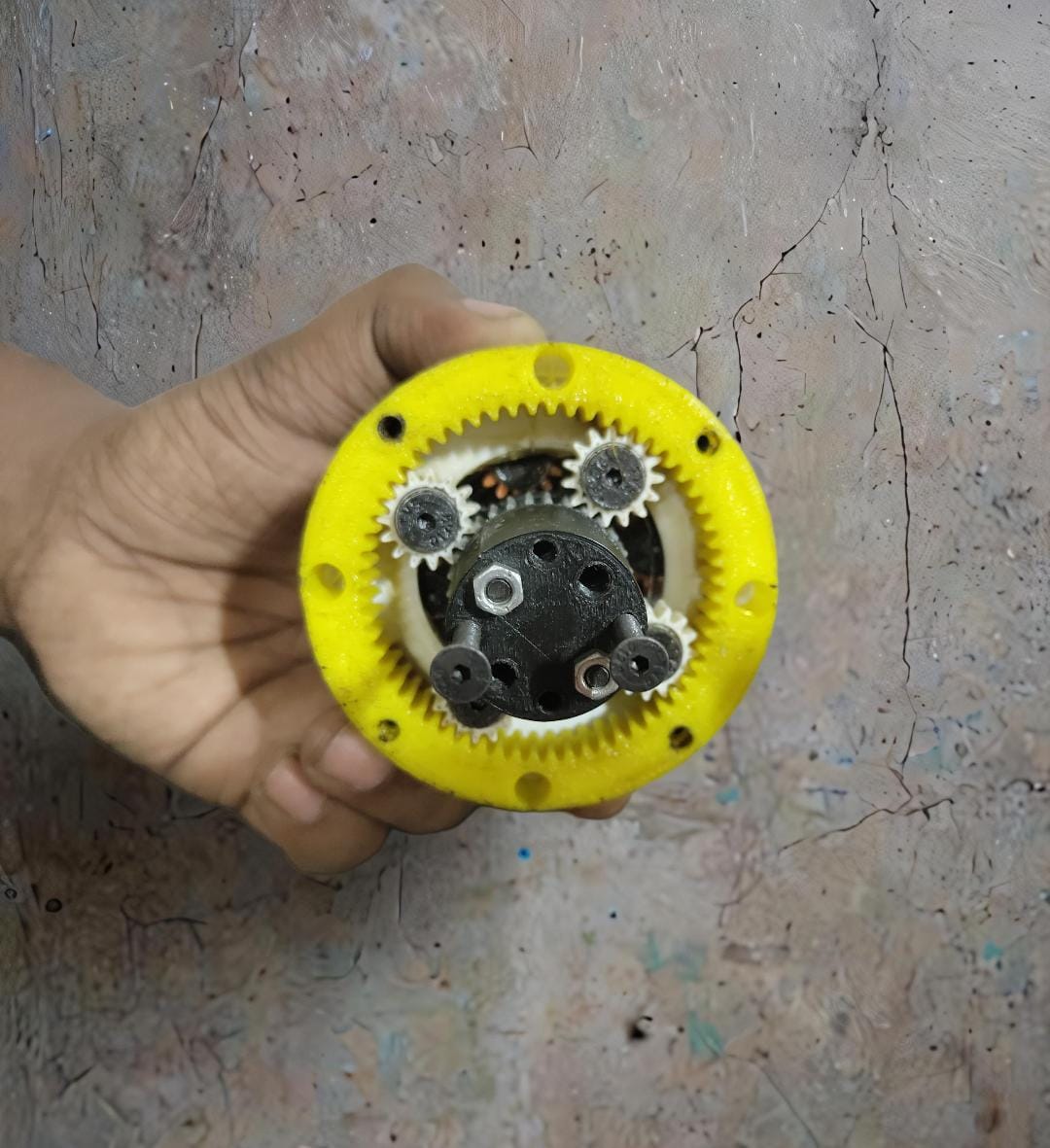

Sun & Planetary Gear Systems:

Simulate load distribution and rotational dynamics with precision-crafted planetary mechanisms that mimic real-world motion. Our designs ensure optimal torque transfer, reduced backlash, and enhanced durability—making them ideal for robotics, automotive, and industrial automation applications

-

Harmonic Drives & Transmission Demos:

Showcase compact, high-ratio motion systems designed for precision and minimal backlash—ideal for robotics, automation, and educational applications. These drives demonstrate how advanced gear systems enable smooth, accurate, and repeatable motion control in space-constrained environments.

-

Spur, Helical & Custom Gear Mechanisms:

Demonstrate gear interactions, torque transfer, and the unique dynamics of custom gear trains through fully operational prototypes. These systems help visualize how different gear types affect motion efficiency, load distribution, and noise reduction, making them perfect for mechanical demonstrations, product development, and training environments.

-

Moving Part Assemblies with Thread Integration:

Include functional threads, bearings, and precisely aligned moving components to simulate real-world mechanical interactions. These assemblies help validate design accuracy, mechanical fit, and dynamic movement—enabling engineers to test mechanical behavior before final production.

-

Toleranced Prints:

We specialize in producing parts with highly controlled dimensional tolerances to ensure seamless assembly, precise interference fits, and reliable mechanical integration. Whether it's mating surfaces, rotating shafts, or aligned bores, our prints are engineered to perform exactly as required in demanding real-world applications.

Prints That Speak for Themselves

- Planetary Gear Demo Model: Functional Gear Assembly with Moving Parts.

- Assembled QC Fixture (Go/No-Go): 3D Printed Inspection Jig with Locking Mechanism.

- Flexible TPU Shaft Coupler: Elastic Coupler Designed for Vibration Damping and Flexibility.

- Working Threaded Enclosure: Twist-to-Close Container with Perfectly Aligned Threads

- Dual-color Motion Model: Contrasting Print Layers to Visualize Rotational Dynamics